Today, Peninsula Town Center in Hampton, Virginia, is the premier shopping destination in the area. Featuring nearly one million vibrant square feet of open-air design, the center draws customers from across the region with its eclectic mix of more than 70 specialty stores and restaurants. But it wasn’t always this way. Built in 1973 and originally named Coliseum Mall, the enclosed mall failed to keep up with changing consumer trends. By the 2000s, stores were closing, existing tenants were struggling and the mall had earned unwelcome recognition on deadmalls.com. Making this retail center relevant again would require the largest redevelopment project in the city of Hampton’s history – a challenge made even more complex by the fact that anchor stores and surrounding out parcels would remain open throughout construction.

One Kitchen, Plenty of Cooks

“Composed of many interconnected parts” reads the definition for “complex” – an apt description for this revitalization project considering the number of stakeholders: An owner in New York, a mall developer from Ohio, a design architect out of Baltimore, and an Ohio-based architect. With so many parties involved, the team from Hoar Construction anticipated it would receive disparate input, opinions, and perspectives. While we knew everyone had the best interest of the project at heart, we also knew we had to get everyone on the same page about the project’s path. Otherwise, delivering the project on time and within budget would be impossible. To ensure a successful outcome, we started meeting months before construction began – and continued in-depth communication throughout the project. This pre-planning and continual communication proved invaluable, keeping all parties satisfied and, more importantly, the project on schedule.

The Loop Widens

Beyond the key stakeholders, the Hoar Construction team also had to make sure tenants and mall management stayed in the loop. After all, shopping would take place and merchandise would still be delivered during construction. To this end, the team made it a practice to consult regularly with these groups. We relayed information and plans well in advance, giving tenants ample time to coordinate deliveries with their suppliers. We also resolved one potential complication – the removal of old utilities and the installation of new ones – through vigilant communication. By partnering with mall management, we determined that the most seamless changeover could only happen by making these updates after the shops closed. For a week and a half, the team worked through the night to install new water, power, and HVAC. This resolution may have cost our crew some sleep, but it also kept the mall open – an absolute must for a struggling mall during the holiday season.

Getting Ourselves Out of a Jam

Redevelopment for Peninsula Town Center extended beyond the confines of the old mall to the surrounding roads. Plans included tearing up medians, constructing turn lanes, and adding a four-way intersection with traffic signals at the new entrance. Not unusual for a project this size, but it did add an additional challenge since the Center sits in the middle of a heavily built urban area, edged on three sides by city roads and on the fourth by I-64. The real challenge, however, came not in the building aspect, but in developing a construction schedule. Through weekly meetings with city officials and state highway representatives, we developed a schedule that restricted construction during peak traffic times and had minimum impact on traffic flow at all other times. This schedule left few daylight hours for road construction, but, by working efficiently, it was all we needed to keep the job progressing as scheduled.

Stewards of the Land

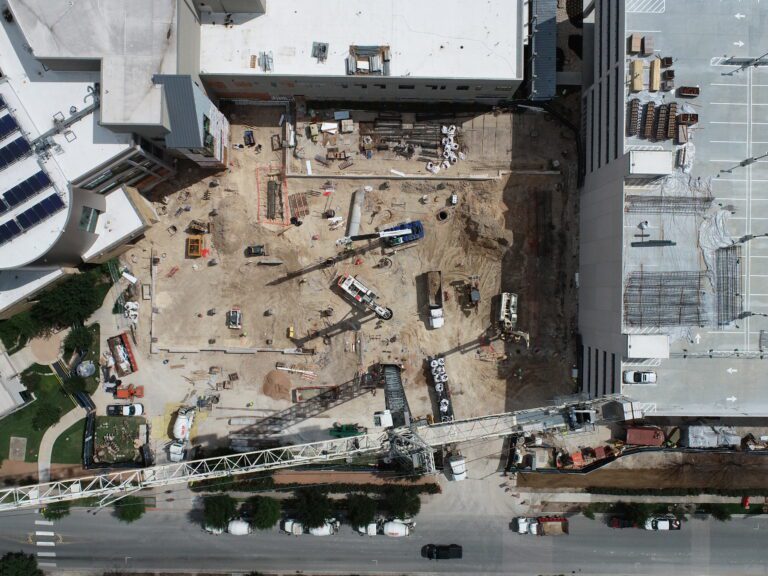

At Hoar Construction, we count stewardship among our core values, holding ourselves responsible for the resources entrusted to us. Not only for the good of the community now but also for the good of future generations. As we proceeded, Peninsula Town Center gave us ample opportunities to put this value into action. For instance, during the demolition of an outbuilding that had been an automotive service center, we discovered leaking underground tanks – and that the site was on an Environmental Protection Agency hotlist. Before construction could begin, we had to clean the site to meet the EPA’s (and our own) standards. Additionally, a restaurant built on the site of an old fueling station had chemicals seeping up through the ground. The cleanup process involved pumping out groundwater, filtering it, and then pumping it back into the storm system. When we uncovered new soil, it had to aerate undisturbed until the volatile chemicals had dispersed. Only then could construction proceed. Another stewardship opportunity occurred during the demolition process that saved the owner thousands of dollars and diverted 32,000 tons of waste from the landfill. Following standard industry practice, concrete from the demolition would have been trucked away to make room for the new construction. But what’s standard for the industry isn’t for us. Instead, we crushed the concrete material where it lay, turning it from rubble into aggregate, and used it for fill under the parking lots and new building slabs. No one will ever see this material, but knowing it’s there – and knowing we lived up to our values – made this undertaking worthwhile for us and for the owner.

Innovation at Work

The architect designed the new mall to reflect the classic look of an established development, with cornices and other architectural details of a downtown shopping center blending seamlessly with modern conveniences. For most of Peninsula Town Center, following this design simply required meticulous attention to detail. But for one three-story building, we had to do more than follow plans; we had to find a new way to bring the design to life. This building stood a full story higher than the surrounding buildings. As a result, it couldn’t be built using the same techniques as the rest of the mall. To deliver the look, feel, and quality the client desired, our team recommended using a tilt-up process in which we formed the concrete elements horizontally and then raised them after they had cured. For this innovation, we not only received positive feedback from the owner but also an award from the National Precast Concrete Association for our use of the technique.

Facing a Labor Shortage

As a course of business, Hoar Construction uses local subcontracting firms and labor in order to support the communities in which we’re working. In the case of Peninsula Town Center, however, we faced a robust construction market and a location near Langley where high-paying government projects were drawing qualified subcontractors. With good help proving difficult to find – and needing the project to proceed seamlessly – we drew upon our nationwide network of contacts to bring in highly qualified subcontractors. At first glance, bringing in out-of-town crews (some as far away as Florida) may sound more expensive. However, thanks to our 70 years in the industry, we have worked with subs from across the country. These partnerships mean the crews know how to work with Hoar Construction and understand our expectations for quality, so they can get up to speed more quickly and perform at a faster pace. As a result, they can often provide our clients with a better value.

A Higher Purpose

After months of work and with little disruption to shopping, our team demolished an outdated structure and replaced it with a vital retail center. Today, residents of Hampton can work, shop, and dine at a destination that delights them with its variety, style, and ambiance. And this is the reason why we’re in the construction business. For us, it’s not about improving structures. It’s all about improving communities.

Learn more about our retail construction experience here.