Our client, Texas A&M University, had been through multiple HVAC replacement projects on their campus — of all them challenging and most of them not completed on time. They needed a contractor with exceptional lean capabilities who could complete the HVAC replacement of a 4-story, 240-room residence hall, in just 11 weeks. Based on the lean construction project approach we outlined during the selection process, we were hired as the construction partner for the Aston Hall HVAC renovation and ultimately delivered the project 5 days ahead of schedule.

First Step, Last Planner

Our approach to successfully delivering the HVAC replacement at Aston Hall started with a Last Planner® boot camp in partnership with the Texas A&M Facilities Planning & Construction team and MEP design partner, Jones/DBR. Jones/DBR was a part of the most recent residence hall HVAC replacement and had an intimate knowledge of past challenges. The collaborative spirit of the Last Planner® bootcamp helped our team identify solutions to avoid past HVAC renovation issues and identify crucial project milestones that must be met in order for the renovation to be a success.

The foundation of a Last Planner® bootcamp is rooted in “pull planning”, a lean construction practice that starts with the end goal and works backwards to develop a coordinated sequence of events that all contributors commit to in order to maximize work efficiency until the final task is complete.

Managing Materials

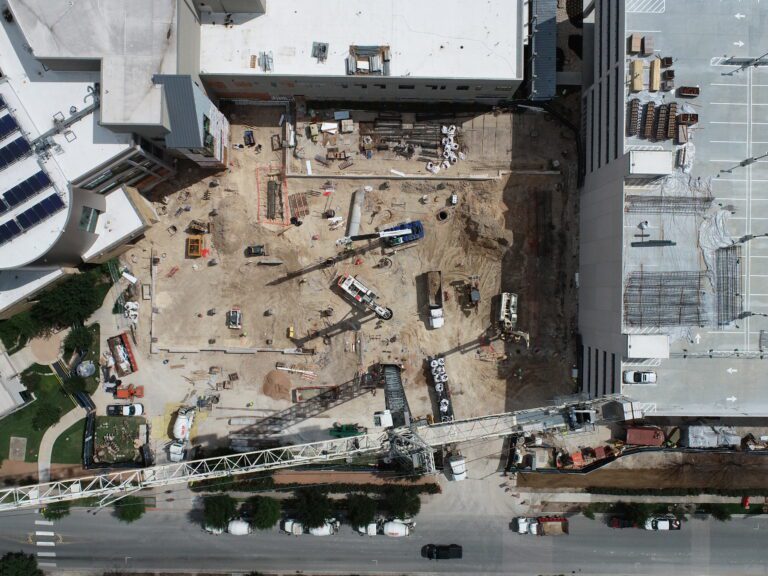

Planning at this level of detail and organization gave our team an opportunity to work with trade partners to identify long lead time materials and complete early buyout packages to maximize work flow. A common challenge of working on a busy college campus is the lack of lay down area. To work around that issue, we rented a warehouse off campus and had all our materials delivered there. All of the duct work was stock piled at the warehouse, preassembled, and then delivered to the job site at Aston Hall as needed — keeping the site clean and the flow of work running smoothly.

Exceeding Expectations

By meticulously planning the project during preconstruction and applying lean methods throughout construction, our team was able to replace the entire HVAC system, install 16 custom air handlers, change out 600+ light fixtures, and upgrade the fire alarm system in less than 2 months. Another benefit of efficient planning during preconstruction was an effective budget. By eliminating waste in the budget and closely monitoring costs, our team picked up additional scope to add kitchenettes in the residence hall without impacting the original project budget. Five days before our client’s deadline, we obtained the certificate of occupancy and Aston Hall’s resident advisor moved in the same day.