We believe there is always an opportunity to do things better, especially if we make time early in a project to look for ways to improve our original plan. That’s what our team did while building an expansion for the Gestamp Alabama Plant 2 in McCalla. Our client’s operation had outgrown the existing building on property, and they brought us in early for a design-build partnership to help plan and build an expansion. The challenge was demolishing the building’s exterior wall, building a new structure, and tying the two buildings seamlessly together, without negatively impacting the manufacturing plant’s ongoing work. By studying the drawings for both the new and existing building and constantly looking for ways to improve our plan, and through regular collaboration with our client and plant employees, we were able to offer suggestions and solutions during the design phase that improved the efficiency of construction while ensuring the plant remained operational so our client could deliver on commitments to their customers without interruption.

The Road Less Traveled

One of the first challenges our team faced to keeping the plant operational was planning the construction of a new road. There was an existing ring road that ran through the middle of the expansion site and was crucial to the plant’s daily operation. It had to be demolished to make room for the expansion and a new road needed to be built in a different location. The original plan was to build the permanent, replacement road first, and then start demolition. During the early planning process, our team realized that plan added unnecessary time to the schedule, and it would be much more efficient to build the building first and the road last.

We studied the property map and located an old, abandoned driveway that connected to the main highway, and gave clear access to the plant without impeding construction progress. Our team made the abandoned driveway usable in much less time than it would have taken to build a new road, allowing us to start demolition sooner — saving a month in the schedule. Properly cutting the temporary driveway to connect it to a highway required several permits from multiple agencies. Our team worked with city, county, and state agencies as well as our team of civil engineers to secure every required permit and keep the work ahead of schedule.

Putting Up Walls (Just to Tear Them Down)

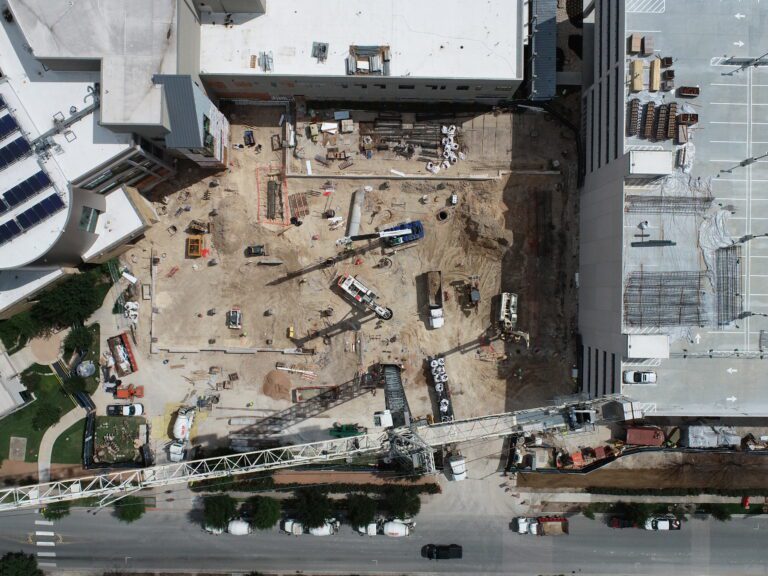

To build an expansion to an existing building, you have to eventually tear down the existing exterior wall. The challenge with that is our client’s operation building parts and components for automobiles must remain climate controlled at all times. Our original plan was to first build the entire expansion structure and then remove the existing wall, ensuring the interior was never exposed to the elements. The risks involved with that plan was our team would work slower and have to be exceptionally careful while removing the wall so we didn’t damage the new property. In addition, we’d have to delay installing our client’s expensive equipment and machinery in the new expansion area until we could remove the wall and clear the space. To find a better way, our team used the pull plan technique to schedule the work and realized it would be much more efficient to build a temporary wall just inside the existing wall, and then tear down the existing wall prior to building the expansion area. This would allow the new construction to proceed at a faster pace with less risk. With the temporary wall in place, we were able to simply tear the wall down and remove it from the property as opposed to carefully removing it towards the end of the project. Our client’s operation was never exposed to the elements and we avoided the risk of damaging finished work, adding time and cost onto the project for rework.

More Efficient = More Value

If you’re extending a building, it makes sense to essentially design the building with all the same systems and components as the existing structure. However, during our early planning and discussion with our client about their operation, we realized there were existing issues that we wanted to look into. The plant’s equipment routinely had maintenance issues that we discovered were caused by inefficient mechanical systems. For example, the facility was producing water hotter than required for their machines to operate effectively, which was causing the machinery to break down. If we installed the same mechanical systems into the new structure, our owner’s problems would only increase. Instead, our team investigated the plant and its systems and suggested solutions during the design phase that would increase the operations efficiency, optimize the machinery’s performance, and reduce operating costs. In addition to making the changes in the design of the new structure, we replaced mechanical components in the existing building to improve the plant’s entire operation.

Working Above and Beyond

The delivery date of our client’s equipment for the expansion fell before we had originally scheduled the overhead work of installing the bus ducts and bus plugs. To avoid working above the new equipment and reduce the risk of damaging it, our team worked closely with our client to build a CAD drawing of where all the mechanical and electrical work needed to be installed, and then marked the structure so our trade partner could begin installation faster than scheduled. By working closely with our client and planning the entire project early, our team was able to get the majority of the overhead work completed before the equipment arrived.

Like all projects, our team first created a construction plan based on the available early information. However, we weren’t content to stick with the first plan if it wasn’t the best plan. We studied new and existing drawings, collaborated with the operations and facilities leaders at the plant, and constantly looked for ways to improve the project to create more value for our client. Because of the team’s proactive approach to planning at every stage of this project, their plant remained operational the entire span of the project and our team was ready to receive their equipment when it was delivered so they could start producing product for their clients without delay.

Learn more about our other industrial and manufacturing projects here.