By Jason Sneed, Project Manager

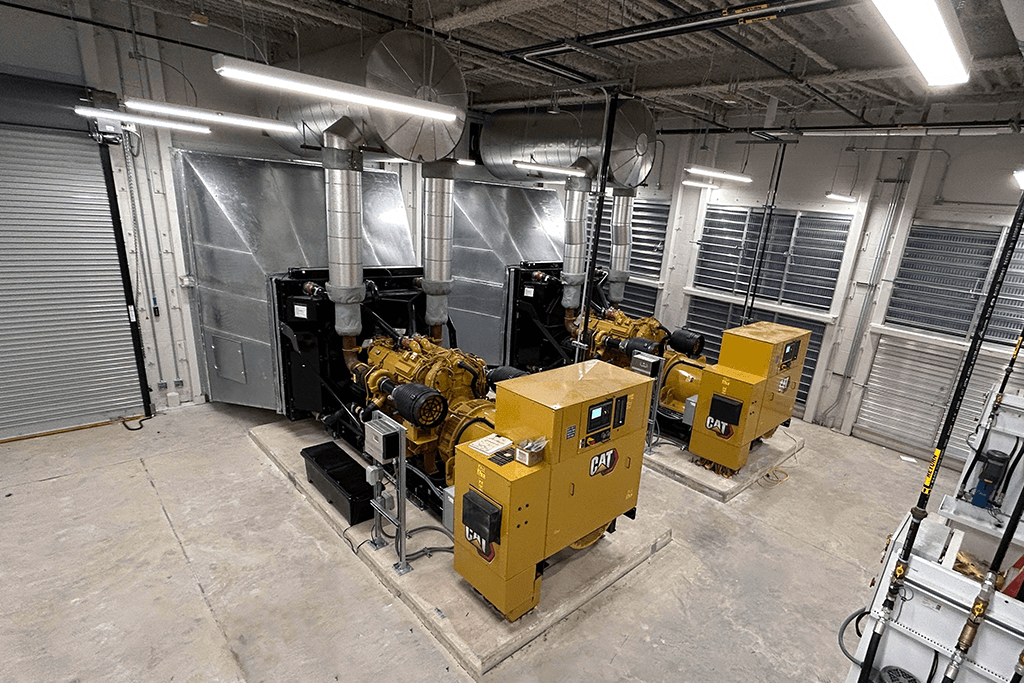

Power shutdowns in active hospitals are a common and necessary feature of most renovation, addition, or improvement projects for healthcare clients. They are also one of the most complicated and potentially dangerous construction operations a healthcare builder can perform. Think about it, temporarily shutting off power to any part of an operational hospital can have dire consequences if the work hasn’t been intricately planned out and precisely managed. This activity is one of the many reasons healthcare construction stands out from other market sectors, and why it requires an experienced and thoughtful general contractor to successfully tackle projects on active campuses. My team and I recently led an exceptionally complicated power transfer from an existing generator plant to a replacement plant on an active hospital campus in Zephyrhills for our client AdventHealth. Our team relied on proven processes and practices to study, plan, and create an action plan to successfully test, shut down, and switch over all power within the hospital and I’d like to share some of those best practices here. These four processes are crucial and, if employed by the right team, can produce successful outcomes during a stressful and critical operation.

1. Face to Face Conversations, and Lots of Them

This is the most important first step in planning and coordinating a power switchover inside an active healthcare facility, and an absolute non-negotiable. On our recent project at AdventHealth Zephyrhills, our team sat down with key hospital personnel to fully understand their operation so we could develop a logistics plan. This wasn’t a one-off meeting, our team met daily with hospital leadership and medical staff to go over the planned surgeries for the day, so we knew the best times of each day to cut power to sections of the building as we worked on electrical panels to install new components and pull the wire from the old building.

Identify who needs to be in the room for these meetings, i.e., facilities management, doctors, nurses, surgeons, and top administrators. You want your project team to grasp a full understanding of the day-to-day operation of the hospital as well as a detailed schedule of all planned surgeries. This information will help them identify the best times to plan tests and shutdowns, when the least amount of activity and patient care is expected. In our case, we performed most of the work on our project after 5pm and stopped work usually by midnight.

2. Plan for the Unexpected

While having a schedule of planned surgeries and procedures is a useful tool in coordinating construction activities, emergency surgeries occur daily inside hospitals and cannot be planned for. So, construction teams must have a solid plan in place to accommodate those unexpected, but inevitable events. On the AdventHealth Zephyrhills project, our team carefully monitored which sections of the building, including multiple operating rooms and the Emergency Room, would be without power and at exactly what times. We worked closely with the hospital to ensure two operating rooms remained fully powered and functional at all times. These two unaffected operating rooms gave the hospital confidence that they could treat patients who required emergency or unplanned surgery during any of the scheduled power shutdowns or tests. An experienced team will be able to create a tailor plan for your project based on patient population and surgical volume to ensure you can continue to meet the needs of patients throughout any improvement or expansion project.

3. Maintain the Environment

When discussing healthcare construction, it is understood (or it should be) that infection control is paramount. A strict and highly monitored ICRA plan must be developed during the early planning stages, and in my experience it’s something clients often require before even selecting their builder. But looking beyond that, there are many other delicate environmental factors hospitals must maintain to ensure patients are healthy, comfortable, and safe — environmental factors that do not exist on most construction sites. For example, AdventHealth Zephyrhills required humidity inside their operating rooms to remain under 50%. Well, when you shut down power and HVAC systems in a hospital in Florida, keeping humidity out is a challenge. Our team solved the potential issue by diverting power to exhaust fans on the building’s roof to maintain humidity levels throughout the hospital despite the temporary shutdowns.

4. Coordinate, Communicate, and Collaborate

One of the things I love about our industry is the teamwork that is essential to our success. Successful general contractors rely on good relationships and productive communication with trade partners and design partners. Effective communication is even more vital in healthcare construction. As we already discussed, successful builders are having daily meetings and conversations with key hospital personnel. It is their job to either bring in key trade partners to those meetings or relay the exact discussion back to trade partners during daily huddles. A plan is only effective if it’s fully understood by everyone who plays a part in it. On the AdventHealth Zephyrhills Generation addition project, we had to install two 500-ton temperature chiller plants inside the hospital, each with its own, separate power. Our team had to develop a plan to get as many connections as possible in place and tested, before shutting down the old power connection and getting the new plants connected and the power turned back on.

It only took our team one day to complete the temperature chiller installation, but it required two full months of planning. We updated hospital leadership on the plan during every owner’s meeting. Our team relied on constant check-ins throughout the entire project leading up to the chiller installation. We would meet with all involved trade partners the day before each electric panel was worked on to ensure nothing had changed in the hospital’s schedule or our own plans that would impact the expected work.

In the end, our team successfully rerouted power from the old plant to the newly constructed generator plant without any negative impact to the hospital’s operation, or more importantly, patient care. We accomplished that by relying on proven and effective processes and practices, mainly — meeting with hospital personnel often, planning for the inevitable unexpected, including environmental considerations in our plan, and constantly checking in and communicating with everyone who played any role in the plan, to ensure everyone was armed with the right information to get the job done.