When we’re involved early in the planning process, we can better help the team stay aligned with project goals. That’s exactly what one of our Texas multifamily teams is doing. By managing the preconstruction process, working with the design team to create deadlines for critical milestones, and providing cost information for target value design, we are ahead of schedule for an early construction start on a 292-unit garden-style apartment complex.

Managing the Preconstruction Process

From the beginning, we understood the owner’s requirements from a budget and schedule standpoint. With that knowledge we were able to drive the design process toward those goals. So, as we’ve gotten new building design documents, we have already vetted the cost implications to ensure we are leading the design team to conform within the target budget. Senior Project Manager David Hill has provided strong leadership to this process; it’s the difference between just letting something happen and making something happen.

Meeting Critical Milestones

This is our fourth project with the owner, so they have been very open to our early involvement and pull plan use in the design phase. Pull planning has allowed the team to be more efficient and to meet the original deadlines we set months ago.

We entered the process during the schematic design phase, with the ultimate deadline to start construction by Aug. 27. We worked backward through pull planning and set up deadlines, which has proven to be very successful in this phase of the construction and design process. By implementing pull plan huddle meetings with the design team and owner, we built a schedule together, which has helped us stay on track and meet our overall design milestones.

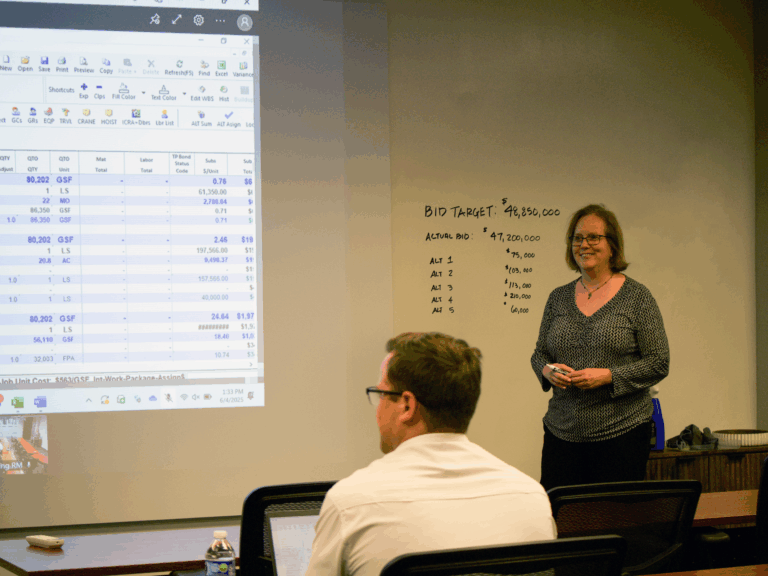

Using Target Value Design

Target-Value Design turns the current design process upside-down. Instead of getting a design and determining whether we can build it and make the owner’s budget, we collaborate to plan and re-plan a design that we know is constructible and is within the budget parameters.

Target-Value Design allows us to review how well we are meeting the needs of the owner during the design process. Most importantly, it helps us avoid delays, rework, and out-of-sequence design, ultimately saving time and money.

The result of our work was that we uncovered a potential one-month design delay early in the process. Through this collaborative team approach, we brought the schedule back within our owner’s expectations.