The First Step to A Successful Project? You Guessed It.

I’ve written a few blogs for our website and in most of them, I find myself preaching the importance of early contractor involvement. In fact, I doubt there’s an article on our website about preconstruction that doesn’t discuss the considerable benefits of hiring your contractor as early as possible in a project. In just my own project experience, I can think of countless examples where our feedback provided during preconstruction helped add value through improved schedules, budgets, quality, etc. But today I think what might be more impactful and relevant is to highlight how early contractor involvement can safeguard projects against current challenges in our industry.

Unpredictability. That’s the biggest challenge our industry is currently facing. The COVID-19 pandemic has caused uncertainty in everything from materials procurement to our everyday health and safety. We outline the cumulative effect of COVID-19 on our industry in this whitepaper. All of us have had to adapt and learn how to operate in this new climate. Virtual meetings seem easy and familiar. Social distancing and sanitizing stations on project sites are commonplace now. Even with all the changes we’ve gotten used to and incorporated into our new normal routine, there are still plenty of unpredictable market factors that could threaten the progress and success of projects in the future.

Current Unpredictable Climates

Let’s look at the supply chain for materials, appliances and commodities used in the construction industry. You can’t build without building materials, so when supply chains are disrupted, the entire project is disrupted. A good example of this is lumber. When COVID-19 hit the United States, construction temporarily slowed as contractors and owners determined how to safely continue work. Demand for lumber was down, so prices started falling. Lumber mills decreased production, and some even laid off workers to avoid building a surplus of materials they couldn’t sell. What they couldn’t anticipate was the sudden boom of home improvement projects. With the shift towards working remotely and the need for social distancing, people found themselves at home and able to tackle home repairs and additions. Plus, interest rates decreased, which motivated people even further to add onto existing homes or build new ones. Those factors combined caused a rebound effect, and the wood demand spiked; lumber futures almost tripled from March to September last year.

With demand aggressively rising, the lumber mills had to scramble to get production back online, and multiple factors made that difficult. For one, they had to hire back laid-off workers or find replacements for those who had gotten new jobs. Like everyone, they had to implement increased health and safety measures and shut down their operations if there was a COVID outbreak. In short, the supply is limited and hard for independent contractors to get their hands on — a perfect recipe for a price surge.

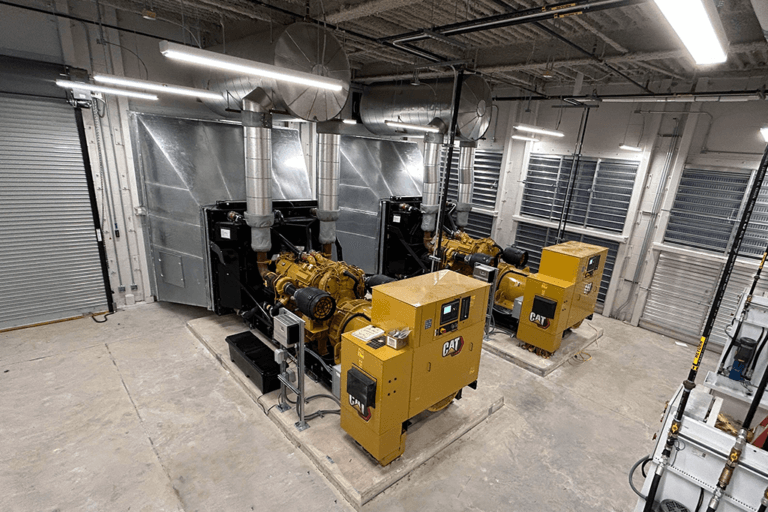

It’s not just lumber, several months ago you were hard pressed to get your hands on appliances like kitchen appliances, washers and dryers, and HVAC units. More recently, we’ve seen delivery delays and supply shortages of switchgear and heavy electrical components. And the cost of steel recently increased by 25%. Some of these issues can be traced back to individual plants forced to shut down due to COVID-19 restrictions or outbreaks. It’s impossible to predict which materials will be impacted next. When you can’t predict, you have to plan.

Say It With Me Now

That brings me back to early contractor involvement. I know…“here he goes again about the value of preconstruction” — but the fact is, the earlier you’re able to plan a project, the less vulnerable you will be when the unpredictable occurs. Hiring your contractor at the beginning of design to work side-by-side with the design team and help identify readily available materials, track budgets, study design options, perform constructability reviews, analyze trade contractor availability, and define schedules all help to reduce your risk of the unknown. If the cost of glass suddenly skyrockets in six months, your project won’t be negatively impacted. Why? Because your contractor planned ahead and already locked-in the glazing package with a trade partner. The alternative is the old traditional building delivery method of design-bid or handing-off the completed design to the contractor with no input along the way. In this scenario, the contractor is merely reporting exactly what the market is telling him, regarding cost and schedule, at the time of bidding with little or no pre-planning. It’s not only less productive but could lead to higher costs and probably more headaches for everyone involved.

That’s why our company is so passionate about early contractor involvement. We want to deliver the best possible project and experience to our clients. And we know the best way to do that, is to plan early and prepare for the unpredictable. And in these uncertain times, a little certainty can go a long way.