Modular construction isn’t new. In fact, it’s more than a century old. (The building method was used during the post-war boom for social housing in the 40’s and 50’s, for example.) Why then, does it seem to be featured in so many headlines right now as if the building method is a novel idea? Our own company has written about the topic several times recently; click here or here to read more. The reason we’re talking about offsite and modular construction for our industry lately is that current conditions make these building methods a very viable option for certain projects. There are really 3 factors driving the recent and ongoing push for more consideration towards modular design and construction:

Market Demands

The healthcare, hospitality (specifically hotels), and multifamily market sectors are driving a demand for offsite and/or modular construction. At the forefront are the multifamily and hospitality markets. With multifamily, it’s the consistent and foreseeable demand for affordable housing in regions across the country. For hotels, project locations and speed to market make offsite construction an appealing option. For example, here’s an article on Marriott International’s push towards modular construction. But let’s look closer at the healthcare sector. Of course, the COVID-19 crisis is creating a desperate demand for additional healthcare facilities that can be erected fast. But, even before the current pandemic, innovative developers were considering modular construction more to meet demands in the healthcare industry. They observed that as people move farther outside downtown areas, the public will still expect immediate, convenient, and reliable access to healthcare providers. Furthermore, the more rural areas will continue to be a challenge for hospital systems as developers analyze site locations and proximity to their larger healthcare facilities.

Select healthcare leaders have already addressed these needs and have initiated aggressive construction programs utilizing the modular approach. Their modular approach has demonstrated consistently shorter onsite construction schedules with dependable quality. When planned properly, completed rooms (volumetric modules) for a facility could be built off site and delivered just as the foundation is completed. This forward-thinking strategy can easily bring essential services to the community months sooner, some data suggests 50% faster. Those kinds of results are invaluable for healthcare clients looking to meet unfilled demands and patient needs in their communities.

Labor Shortage

The labor shortage continues to plague our industry. And the skilled tradesmen/women that are in the workforce are at the back end of their careers. The newer, younger labor force numbers are simply not meeting the demand. This challenge is prominent when staffing a large-scale project that requires a lengthy duration but is also an impact to smaller projects. No news there. While I have read many causes of the problem, I have heard few solutions.

Modular construction should be considered a potential solution for a few reasons. The main reason, I think, is that a manufacturing facility can offer very appealing working conditions compared to that of traditional onsite construction. A majority of the labor performed on a modular project is constructed/fabricated in an environment impacted less by heat, cold, rain, or other extreme weather. The labor force travels daily to the same facility as opposed to different job sites for each project assignment and works in a more regulated location. Studies have documented that an average productive workday in a manufacturing environment is 8 hours, whereas on-site production is about 6 hours. That is an improved efficiency of 25 percent! Furthermore, certain modular projects have reported a reduction of necessary onsite labor of nearly 90 percent. Common sense tells us, regardless of the exact numbers, less manpower on site equates to less congestion and a reduction of waste — a central tenet of Lean construction. If your project is offering these benefits and positive working environment conditions, it can give you an advantage in this very competitive labor market.

Industry Leadership

Waste has long been the toughest issue our industry faces. Construction industry studies show more than 50 percent of time in the field is wasted on unproductive work or activities. I’ve noticed a focused shift by some of the leading contractors in our country to try to eliminate waste throughout the entire design/construction process by Lean construction methodologies. I’m especially proud of our own company’s commitment toward improving industry practices and our approach to building smarter. Our digital tools (i.e. BIM, virtual reality, 3D technology) and quality initiative procedures can enhance the entire lifespan of a project from the preconstruction phase of design coordination to the manufacturing and on-site construction phases of work. You can read more about our company-wide goal of continuous improvement

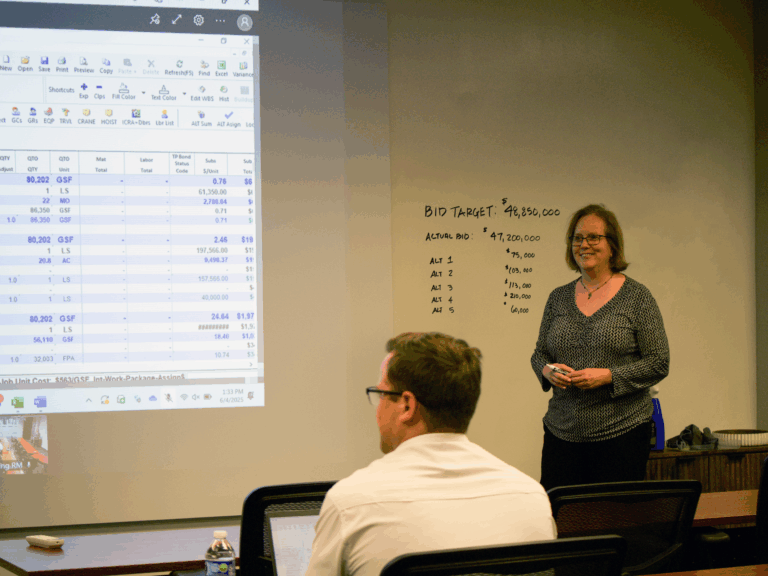

We have also experienced our clients pushing us, the general contractor, more and more to be innovative and be an instrumental part of advanced building processes with designers and engineers. We’ve embraced these challenges as this mindset benefits all involved. Just recently, we responded to a healthcare project where the client wanted us to present not only our estimated budget and schedule, but also our plans to find innovative ways to optimize their project, reduce waste, and build their facility more efficiently. That kind of pioneering leadership across our industry, from contractors to clients, is why we’re seeing more projects consider modular construction.

At the beginning of this blog, I stated that modular construction can improve the speed and quality of a project. Another benefit is that project costs will be defined sooner. The very nature of the modular approach improves certainty. That is true, but there’s a catch. The project team (client, designers/engineers, contractors, and manufacturers) must effectively start planning early and be committed to making key decisions early. Ideally, you’d hire your design team, modular manufacturer, and qualified contractor in the schematic design phase so they can collaborate to finalize the construction and fabrication documents simultaneously. Crucial decisions, like materials selections and standardized designs, would have to be made and not changed. Why? The manufacturer must source efficiently, develop supply chains, and set up their fabrication lines to begin production. As the modular components (volumetric, subcomponents, or panelized components) are being produced, the contractor has mobilized work to receive the prefabricated products and orchestrate the completion of work. If changes are made late in production or rework has to be done in the field, you’ve lost the modular construction’s edge of efficiency and certainty. The rework and the change orders will significantly increase a project’s costs and jeopardize the schedule.

If speed to market is one of your top priorities, if quality is expected, or if project certainty is a target value, I’d recommend considering modular construction for your next project. To read more about which projects are and are not ideal for the building method, click here.