GD Copper USA, Inc. is a 500,000 square foot precision copper tubing manufacturing facility located in Wilcox County, AL. The building is so large, you could fit nine football fields inside. The facility’s operation required a full assembly line for copper production, which in turn required an extremely complicated concrete foundation. Due to the project’s size, scope, and aggressive 12-month schedule, our team realized early on we could successfully deliver the project while also creating value in their budget if we self-performed the critical path scope of the schedule. This decision proved to be crucial when the schedule required us to pour concrete during one of the wettest winters in recent history.

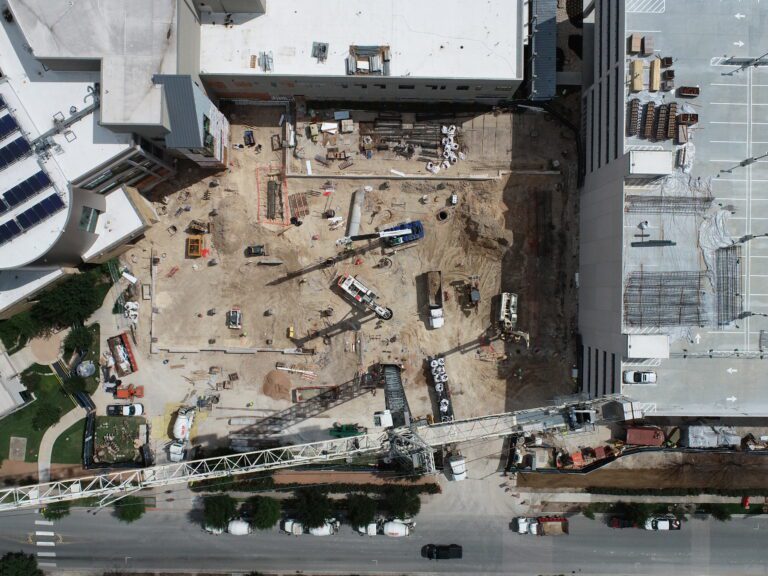

Complicated Concrete

The concrete foundation for the facility had to not only support all our client’s equipment, but it also had to be poured so that each piece of machinery could sit into the concrete. With millions of dollars worth of manufacturing equipment on its way from overseas, we had to calculate the foundation tolerances to the millimeter to ensure each piece would fit perfectly in place. Essentially, we were creating concrete cabinets for our client’s assembly line equipment. If our calculations were off at all, the machinery wouldn’t line up and connect. We poured 21,400 cubic yards of concrete — enough to fill 82 miles of city sidewalk. When our client’s equipment arrived, we were able to install all of it into place without issue due to our extensive planning and precise quality control.

Precision and Prefabrication

Because the concrete work required near-perfect precision, we decided to set up a prefabrication shop on-site to ensure quality. We prefabbed the concrete forms for the intricate concrete foundation and delivered them fully assembled. The forms were then inspected and checked for quality prior to installation. We also prefabricated the holes within the concrete forms to line up perfectly with the anchor bolts used to install the equipment. Our prefabrication efforts not only ensured quality, but it also saved valuable time in the schedule — approximately 4 weeks’ worth of work.

Record-Breaking Rain

While building the copper manufacturing plant, Clarke County, Alabama experienced its wettest winter in 75 years. Fifty inches of rain fell in a five-month period. Our team sequenced our work to install the steel building shell before pouring the assembly line foundations and slabs to provide a weather shield for the concrete. In addition, we lime stabilized the excavations for the building. We couldn’t use wet soil to backfill and we didn’t have time to wait for the soil to dry. Instead, we set up a soil drying process beneath the roof of the building in the shipping and receiving area. We added lime to onsite wet soil to create dry material which made it usable for backfill.

On this project, we mirrored our client’s business and applied assembly line-style methods to our work. Through lean construction efforts like prefabrication, our ability to self-perform the concrete, and innovative solutions to combat the historically wet weather, our team delivered the manufacturing plant on time so our client could open their facility and begin meeting the demand of their clients.