When the first Sacred Heart Children’s Hospital opened in 1969, it allowed specialized doctors and nurses to provide a level of care beyond that of a general pediatrician to the area. That put Pensacola on the healthcare map. Fast forward 45 years, and the need to expand the existing facility to serve the greater Panhandle community was long overdue. Our client was committed to delivering a highly developed hospital that would allow them to better serve their patients, and they trusted us to make their vision a reality. Building a 177,000 square foot new hospital with 37,000 square feet of renovation and backfill along “hurricane alley” was a challenge we fully embraced. Our seasoned healthcare team finished the project ahead of schedule despite the many weather challenges, bringing a clinically-advanced level of care and specially designed facility to the children and families of Northwest Florida.

Don’t Rain On Our Parade

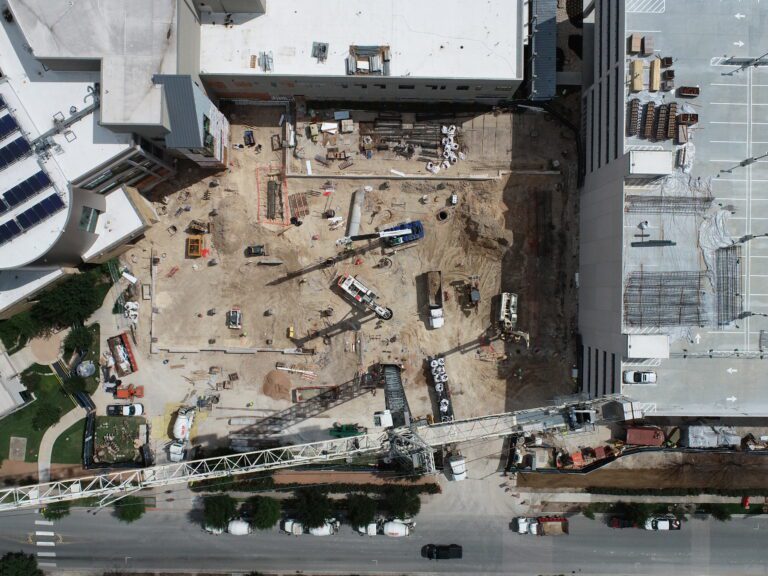

One of the biggest challenges on this project was getting the foundations and underground utilities installed during one of the rainiest years in recent history. Three hurricanes and two tropical storms impacted our schedule, though thankfully not all were direct hits to Pensacola. During the first year of construction, Hurricane Irma made landfall in the Florida Keys as a category 4 hurricane. Our team quickly made the decision to take the crane down. With high winds forecasted throughout Florida and along the Panhandle, we didn’t want to risk the crane falling, especially as it stood over Sacred Heart’s Pediatric Intensive Care Unit, NICU and operating rooms.

Over the course of the project we lost 137 days of production due to weather and received more than 14 feet of rain. The wet weather and the ground water it left behind was particularly challenging because we had to excavate nearly 25 feet of existing soils out of the entire building footprint, including areas below the existing building to install the foundation system. Despite these challenges we were able to complete the project nearly two months early. Our team worked weekends and met regularly with our trade partners to ensure we were scheduling work to flow as quickly as possible. These added efforts meant the local community received access to state-of-the-art pediatric care nearly 60 days earlier than expected.

Efficient Prefabrication

During the preconstruction phase, we explored prefabrication options to control cost and reduce the schedule. Our team designed a rack system that allowed the construction of segmented sections of mechanical and plumbing pipe to be installed, tested, and insulated in a factory-controlled environment. The use of these prefabricated racks enabled testing and inspection to be done from a standing position as opposed to being inspected on a ladder, which creates a safer working environment. The units also helped reduce the coordination and installation time on site because they were fabricated early and installed rapidly when the job was ready for the units.

Constant Communication

Patient safety is the most critical part of our job on every healthcare project. While building the new children’s hospital, we spent a considerable amount of time planning for infection control and cleanliness with minimal noise and mechanical/electrical/ plumbing interruptions. Our plan included interim life safety measures to protect patients as well as visitors and staff. We spent a considerable amount of time developing our plan in preconstruction because we understood there was no room for mistakes while working on an active hospital campus, especially when working near the hospital’s most vulnerable patients in the NICU.

With operations running around the clock, our team scheduled work around the hospital’s activities, working together with the hospital staff to devise a plan to route the patients, employees, and visitors away from construction. We were in constant contact with the owner when working on building systems because our work required us to shut down these systems temporarily to tie in new areas. Shutting down critical, life-saving systems in an active hospital required exhaustive planning and painstaking attention to detail.